Degradable plastics are divided into starch degradable plastic (PLA), biodegradable plastics (PHA), inorganic degradable plastics and photodegradable plastics. Now, PLA/PHA/inorganic degradable plastics are widely used in the market.

The PLA degradable plastics granulator adopts twin screw series with a capacity of 40-600 kg/h.

Corn Starch Biodegradable Recycling Machine

The machine for recycling biodegradable materials derived from corn starch offers two types of granulators for PHA and inorganic degradable plastics. These granulators use an internal mixing single screw series, ensuring high capacity.

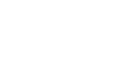

PLA, a biobased plastic with a minimal carbon footprint, is commonly used in packaging, food serviceware, and is now gaining popularity in automotive, electronics, and textiles for more demanding applications.

Enhanced heat resistance is achieved when using high-quality lactides to produce PLA. High heat PLA has been tested to endure temperatures ranging from 100 to 140°C, making it suitable for manufacturing biodegradable films and bags.

biodegradable bag

Biodegradable Film

The Corn Starch Biodegradable Recycling Machine boasts features such as the use of PLA biodegradable and PHA degradable resin, an inverter to control extruder speed and save power, extruders with filter device, a pelletizing unit, and wind cooling unit. The machine comes with a one-year warranty, capable of running nonstop 24/7, with a simple design for easy operation. It is economically designed, suitable for beginners or starters. Machine power options range from 220V to 480V, customized based on request (e.g. USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz). After-sale services include sending an engineer to the buyer’s factory for installation and training. Customized machines or OEM designs are welcomed from customers.

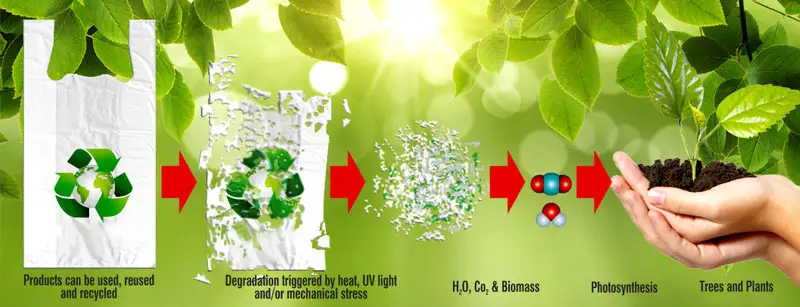

Products made from recycled plastic:

Over the last 10 years more and more products have begun to be produced using recycled plastics. These products span a huge range: from skateboards to reusable bags to even sunglasses. The opportunity for more and different types of recycled plastic products is nearly endless.

ECO Biodegradable Bags machine line

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company