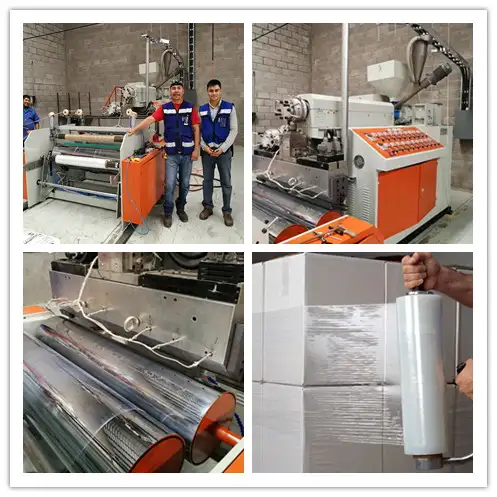

The One Layer Stretch Film Machine is equipped with a single screw, one motor, one inverter, and features a simple design, easy operation, low noise, and stable running. The winding process is controlled by a PLC touch screen. The machine includes an extruder, traction part, leveling part, edge trimming, winding, and automatic roll changing for finished products. Designed for efficient packaging, this machine is suitable for various industries. Commonly known as a Cast Stretch Film Machine, it uses LDPE and LLDPE to produce stretch film for applications such as airport luggage, pallets, cartons, building materials, auto parts, and hardware.

LLDPE stretch film

Introducing the One Layer Stretch Film Machine

The One Layer Stretch Film Machine utilizes a variety of materials including LLDPE, LDPE virgin raw material, recycled material, CaCO3 compound, biodegradable material, masterbatch, and additives. The machine is equipped with an inverter to control film extruder speed, thereby saving power, being environmentally friendly, and reducing costs. It produces films with a thickness ranging from 0.017mm to 0.04mm and widths between 100mm and 500mm, suitable for applications such as stretch film, pallet packing, carton packing, building material packing, auto parts packing, hardware packing, and luggage wrapping.

The machine features a screw material made of 38CrMoAl for long-lasting use, backed by a one-year warranty allowing for continuous operation – 24 hours a day, 7 days a week. With a simple and user-friendly design, this economically designed machine is ideal for beginners or starters in the industry. Operating at various power specifications such as 220V, 380V, 440V, and 480V (customizable based on the user’s requirements), including examples like USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz.

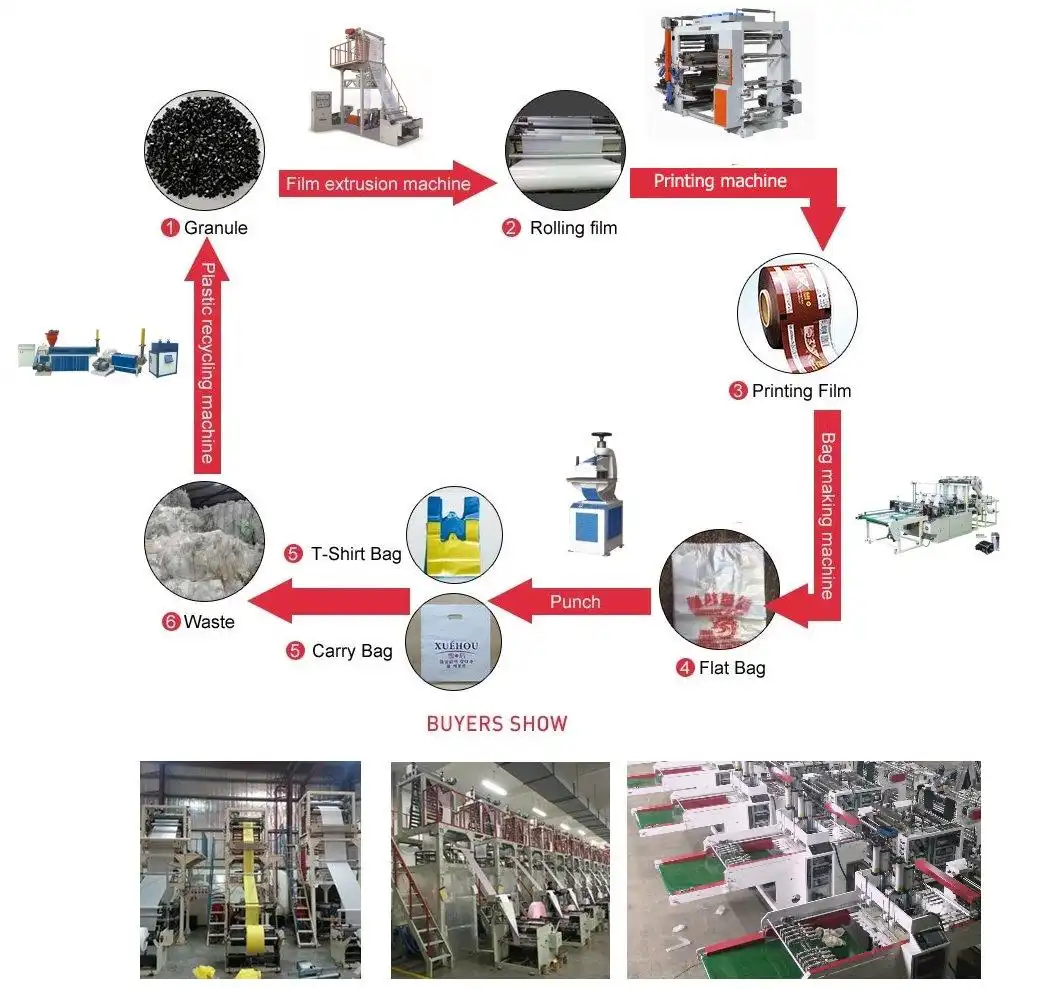

Additionally, after-sales service is provided, offering on-site installation by engineers and training services at the buyer’s factory. Customized machines and OEM designs are warmly welcomed by our company.

Optional Equipment:

1)Auto load

2)Auto dry hopper

3)Motorize net changer

4)Hydraulic net changer

5)gule pump

6.air compressor

7.Chiller

Main Technical Parameter

| Model | KD-50 | KD-75 |

| Material | LLDPE,LDPE,biodegradable material | |

| Screw Diameter | Φ50mm | Φ75mm |

| Film Layer | One layer | One layer |

| L/D Ratio Of Screw | 30:1 | 30:1 |

| Speed of Screw | 10-120rpm | 10-120rpm |

| Film Width | 200-500mm | 200-1000mm |

| Film Thickness | 0.017-0.04mm | 0.017-0.04mm |

| Main Motor Power | 11kw | 30kw |

| Film Color | Transparent,Black,Red,White,blue…bag color changed by mastbatch | |

| Max Output | 35kg | 80kg |

| Heating power | 15KW | 40KW |

| Water Consumption | 0.5m3/h | 0.5m3/h |

| Air Comsumption | 3m3/h | 3m3/h |

| Machine Weight | 3T | 4T |

| Overall Dimensions(L*W*H) | 56*15*18cm | 60*15*25cm |

| Total Power | 40kw | 80kw |

| Power Voltage | 220V,380V,440V | 220V,380V,440V |

| Machine Working time | 24 hours*7 | 24 hours*7 |

| Material Core Diamater | 76mm(3 inch) | 76mm(3 inch) |

| Warranty | 1 year | 1 year |

| Technical Assistance | Engineers available to service machinery overseas | |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Stretch film machine.

Extrusion Film Extrusion use Polyethelene.

Linear Low Density Polyethylene(LLDPE):

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company