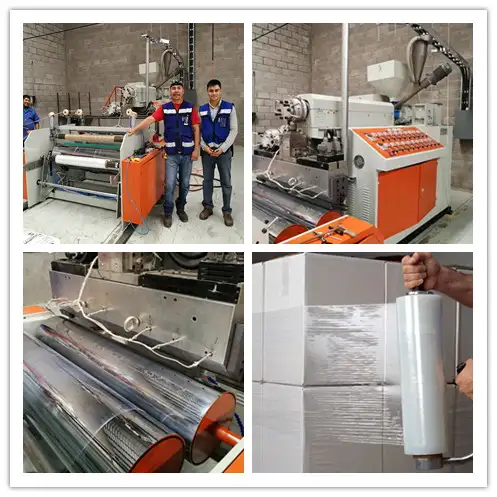

The Three Layers Stretch Film Machine is a specialized device for producing LLDPE stretch film. This machine, which can create film up to 1500mm wide, is commonly used for packaging applications such as airport luggage, pallets, cartons, building materials, automotive parts, and hardware components. The key features of this three-layer machine include three extruders, three motors, three inverters, a simple design for ease of operation, low noise levels, stable performance, and precise control of the winding process via a PLC touch screen interface. In addition to the extrusion process, this equipment includes traction, leveling, edge trimming, and automatic roll changing capabilities for efficient production.

LLDPE stretch film

The Three Layers Stretch Film Machine is equipped with features including the use of LLDPE and LDPE virgin raw materials, recycled materials, masterbatch, and additives. The inverter controls the film extruder speed to save power, promote an environmentally friendly approach, and reduce costs. This machine produces films ranging from 0.017mm to 0.04mm in thickness and 100mm to 500mm in width, suitable for various packaging needs such as stretch film, pallet packing, carton packing, building material packing, auto parts packing, hardware packing, and luggage wrap packing. The screw material, 38CrMoAl, ensures long-term usage. With a one-year warranty, the machine can operate continuously 24/7. It features a simple design for easy operation, making it economically suitable for beginners. The machine’s power supply can be customized based on the user’s requirements, such as 220V, 380V, 440V, or 480V. After-sales service includes the option to send an engineer to the buyer’s factory for installation and training. Customized machines and OEM designs are also welcomed.

Optional Equipment:

1)Auto load

2)Auto dry hopper

3)Motorize net changer

4)Hydraulic net changer

5)gule pump

6.air compressor

7.Chiller

Main Technical Parameter

| Item | 1500mm three layers stretch film machine |

| crew diameter(mm) | Dia.75mm, 65×2 mm |

| Raw Material | LLDPE,LDPE |

| Film width | 1500mm |

| layer | Three layers(A/B/C) |

| Film Color | Transparent,Black,Red,White,blue…bag color changed by mastbatch |

| L/D ratio of screw (L/D) | 30 : 1 |

| Width of die head (mm) | 1800 (mm) |

| Width of finished products(mm) | 1500 (500 ×3 rolls) |

| Thickness of finished products (mm) | 0.008-0.05 (mm) |

| Structure of film layers | Three layers |

| Max output (kg/h) | 150 (kg/h) |

| Linear speed of machinery (m/min) | 50-100 (m/min) |

| Traction power (kw) | 2.2 ×2 (kw) |

| Total power (KW) | 150 kw |

| Overall dimensions (L*W*H) | 8000*4600*3500mm |

| Weight (T)(About) | 5T |

| Air Shaft Diameter | 76mm |

| Machine Working time | 24 hours*7 |

| Delivery Time | 45~90 days |

| Warranty | 1 year |

| Power | Customized based on request (For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz…) |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Stretch film machine.

Extrusion Film Extrusion use Polyethelene.

Linear Low Density Polyethylene(LLDPE):

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company