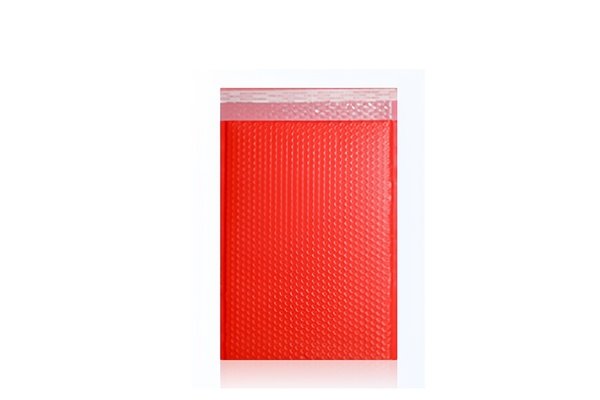

Popular products

Kingdom Machinery Co., Ltd. is a mature company that produces various plastic bag production lines.

Chinese manufacturer of plastic bag machines and blown film machines

As a mature company, we produce various plastic bag production lines, including blown film machines, plastic bag manufacturing machines, flexible printing machines, gravure printing machines, stretch film machines, recycling machines, straw manufacturing machines and other plastic machinery.

- 1500 blown film machine

- film blowing machine

- Installation of blown film machine

- Second hand roof container blown film machine

Latest news

Plastic bag making machine manufacturer – best-selling plastic bag making machine

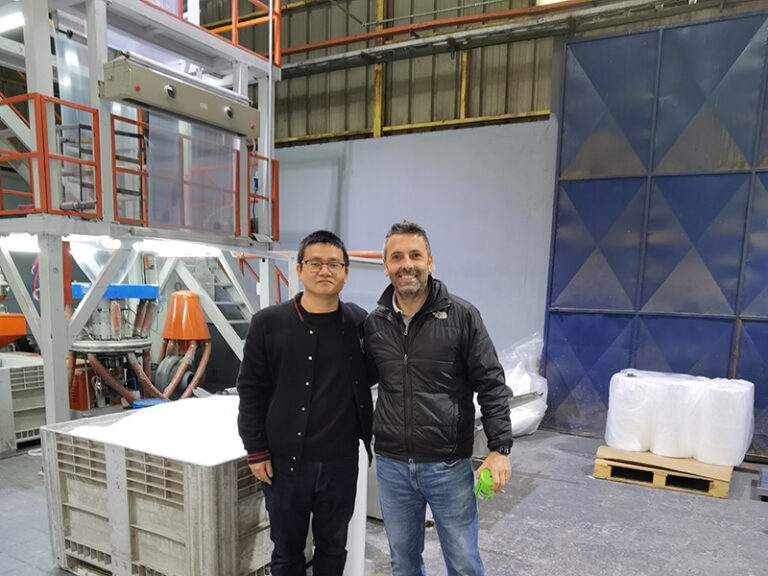

Why do over 1000 customers choose us?

Quality assurance

The final inspection is conducted 100% during the production process, and defective products are controlled between 1% and 3%. These are the two basic quality requirements that we always adhere to. We provide a two-year warranty for all timer switches.

Strong research and development capabilities

Our team consists of one product engineer, two structural engineers, two software engineers, and two circuit engineers, most of whom have experience working in well-known companies or state-owned enterprises.

ONE STOP SERVICE

From innovative generation to final mass production, we offer products customized to your specifications. Whether it’s changing products into logos, labels, packaging or developing a new product, we’re already familiar with it.

Strong production capacity

We have 16 time switch production lines. Our R&D internal laboratory has over 30 perfect testing equipment to ensure optimal product performance, with a total of 26 testing projects including product performance testing.

Competitive prices

Large scale production and well-trained workers greatly reduce costs, and Alion Solution offers the lowest prices, making it the most competitive supplier in your region.

Fast delivery

We have a production line with 16 production time switches, and we always plan to ensure good delivery times. Generally speaking, we can provide samples within 3 days and bulk within 15-20 days.

Frequently asked questions

Are you a factory or a trading company?

We are a factory and we can guarantee that our prices are first-hand, very cheap and competitive.

How does your factory conduct quality control?

All products will undergo 100% testing before shipment.

How long can we get this batch of goods?

For standard machines, we usually deliver within 25-30 days. Delivery of customized machines within 30-60 days.

What should I do if I encounter problems during use?

We offer 24 hours online service.

What is the shipping cost?

The price also varies depending on the port of shipment.

What are the delivery and delivery terms?

The delivery time is 30 days after receiving a 30% deposit, and the balance will be paid before shipment.

Chinese manufacturer of plastic bag machinery and blown film machines

- Since 2005, the Evergreen Machine co.,ltd has installed over 1700 machines worldwide.

- Success and positive feedback from satisfied customers from 102 countries

- Flexible customization of machine design to meet your specific requirements and factory design

- High quality components for energy-saving machines and high-performance motors

- High cost-effective machinery: machines with low investment costs, high quality, and durability

I'm new here.

If you are a novice in the plastic bag industry, please click on the link below to learn more information.